It is anticipated that this trend of smart technologies adoption will continue and grow during the forecasted period. Thus, the COVID-19 pandemic positively impacted the smart manufacturing market. It also offered benefits such as accelerated risk assessment and production time, improved OEE through reduced downtime and improved performance, reduced risks in areas such as product availability and marketplace reputation new business opportunities through mass customization, mixed manufacturing, small-batch manufacturing, improved product quality and enhanced insights into the performance of products in multiple real-time applications and environments. It provided the much-required flexibility to the manufacturing units to change the product design and quickly adapt to new processes as per clients' demands.įurthermore, the digital twin technology drastically reduced the cost of designing products in a single go. It also facilitated remote factory monitoring at greater efficiency irrespective of time and place constraints. Smart manufacturing improved companies' productivity and optimized the workforce required for the same role. Speak to our Analysts to Understand the Impact of COVID-19 on Your Business: These benefits align with the requirement of the new dynamic protocols precedent by the COVID-19 pandemic, influencing the adoption of smart technologies, digital automation, and industrial IoT demand across the industry. The adoption of smart manufacturing has resulted in improved productivity, higher quality, near-zero design error, energy efficiency, leaner process, flexibility in production scale, increased agility, improved predictability, and enhanced process monitoring.

Thus, there is increasing adoption of smart manufacturing technologies from various industries in their production processes.

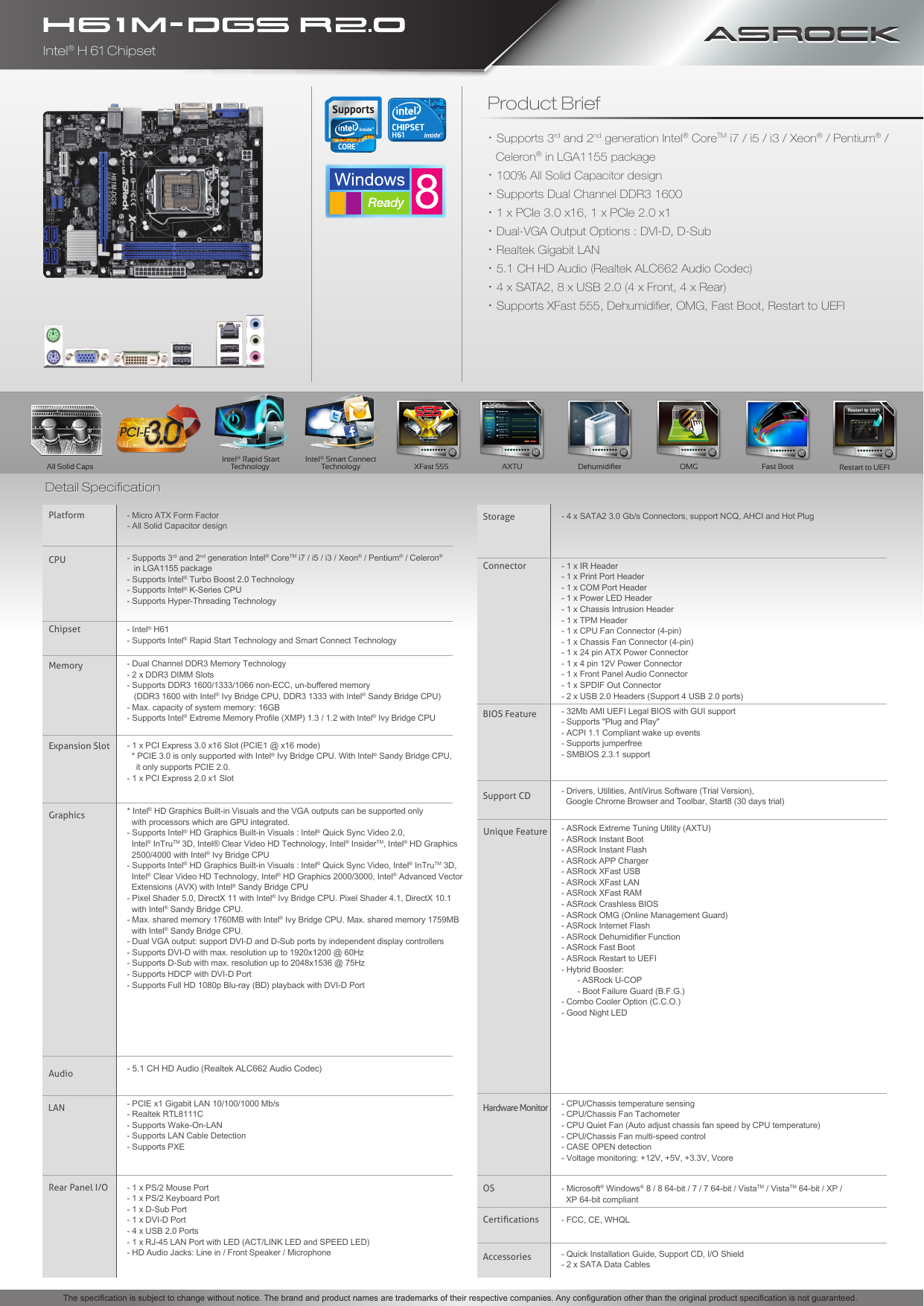

INTEL SMART CONNECT TECHNOLOGY SOFTWARE MANUAL

The COVID-19 outbreak significantly influenced the manufacturing industry by reducing its dependency on manual labor and highlighted the importance of adopting advanced technologies, such as AI, machine learning, and IoT. As a result, several industries stopped their ongoing production operations, which disrupted supply chains and affected the demand-supply balance. Governments were forced to shut down manufacturing plants and halted import-export operations. The spread of COVID-19 severely impacted the performance of several industries and economies globally. Although the macro challenges, such as disrupted supply chains, decentralized workforce, and the provision of safe and healthy employee workspaces, were different than in past recessions, market players had to deal with monumental market dynamics. The outbreak of the COVID-19 pandemic had unprecedented impacts on public health, disrupting industrial structures, halting supply chains, and accelerating social reforms globally.

Impact of COVID-19 on the Smart Manufacturing Market However, the high capital and operating expenses and a lack of standardization for technology platforms are some of the major factors restraining the growth of this market. In addition, the advent of 5G connectivity in smart manufacturing and the proliferation of smart manufacturing in developing countries are expected to offer lucrative growth opportunities for the growth of this market. The growth of this market is attributed to the factors such as the increasing number of government initiatives to promote industrial automation, the rising number of investments in Industry 4.0, growing demand for safety regulation compliance, and high labor costs in developed economies. Redding, California, Ap(GLOBE NEWSWIRE) - According to a new market research report titled, ‘ Smart Manufacturing Market by Technology (Robotics, AI, IIoT, Cloud, AR/VR), Application (Machine Inspection, Energy Quality, and Warehouse Management Planning, Surveillance, Optimization), End-use Industry, and Geography - Global Forecast to 2029 ”, the smart manufacturing market is expected to grow at a CAGR of 21.5% from 2022–2029 to reach $446.24 billion by 2029.

0 kommentar(er)

0 kommentar(er)